|

|

|

OmegaPrep II Thinning warped die to a constant remaining thickness • Die thinning and polishing Read The OmegaPrep II |

||

|

UltraPrep IV Thinning warped die to a constant remaining thickness. • Die thinning and polishing Read The UltraPrep IV |

||

|

RKD Systems MountPlate The sample is wax mounted on the sample holder using the MountPlate. It rapidly heats the sample and holder for mounting and rapidly cools the sample. The sample holder is designed for easy removal and replacement without having to remount or re-align the sample. |

||

|

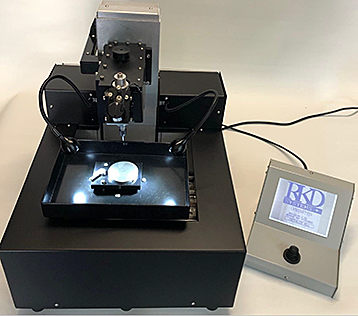

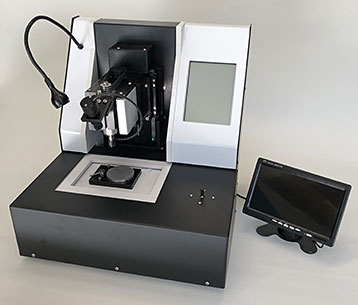

Model 2400 The RKD Systems Model 2400 Continuous flow System is a small, compact, machine that provides a continuous flow of water or lubricant over a die surface during die thinning processes that utilize lapping films. Two pumps provide dispensing and scavenging of the lubricant. One pump dispenses clean lubricant from a source bottle while the scavenging pump extracts the liquid from the process cup and moves it to a waste bottle. Both bottles reside in the system. Level detection is provided to detect a near empty source bottle or a nearly full waste bottle. The bottle housing provides secondary containment and leak detection. Both visual and audible indications provide bottle level conditions and leak detection. The supplied waste extraction assembly clamps onto the process cup providing easy setup without modification of standard tooling. |

||

|

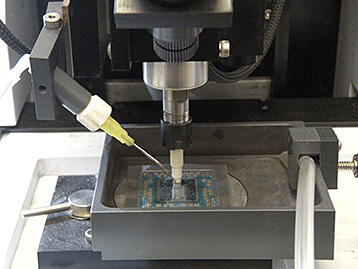

The dispensing assembly clamps onto the spindle carriage assembly of the UltraPrep III or OmegaPrep, allows dispensing through a standard hypodermic needle, and allows precise adjustment of the point where the liquid is dispensed. The continuous flow of lubricant over the die surface increases material removal rates, increases film lifetime, and reduces the tool force on the die. This is done by removing the silicon particles generated by the lapping process. Without a continuous flow of lubricant, the particles accumulate on the lapping film preventing full contact of the abrasive with the die surface reducing the removal rate. The controls are simple with a knob that controls dispensing rate and buttons to start or end dispensing, fill the dispense line, or drain the waste line. |

||